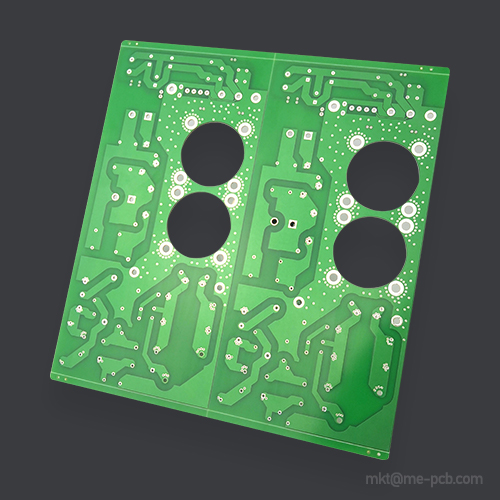

Heavy Copper PCB

8oz Thick Copper PCB

Copper: 8Oz

power supply

Board Thickness: 2.0mm

Surface Finish: Lead Free HASL

power supply

Board Thickness: 2.0mm

Surface Finish: Lead Free HASL

Description

Thick copper PCB products are used extensively in power electronic devices and power supply systems.

Get in touch with us at www.meidearpcb.com

or mail to mkt@me-pcb.com

Designed For High Current Power Systems

The 8oz Thick Copper PCB is purpose-built for high-current and power-intensive applications that demand robust electrical conductivity and superior heat control. Targeted at engineers, power electronics designers, and system integrators, this board is ideal for those seeking durability under extreme electrical loads. By offering exceptional thermal management and current-carrying capacity, Meidear empowers professionals in industries where performance under pressure is non-negotiable. Trusted by global pcb suppliers, this solution addresses the real-world needs of flexible pcb users.

Technical Configuration & Copper Thickness Superiority

At the heart of this board lies its defining feature: an 8oz (approximately 280μm) heavy copper layer. This significantly boosts current endurance and lowers the risk of circuit fatigue or failure. The PCB base is constructed with high-quality FR4 and offers advanced heat dissipation across all layers. With excellent solder mask finish and precise etching, the product also ensures mechanical stability even in fluctuating thermal environments. It is a standout among flex pcb and power pcb options offered by top-tier pcb suppliers.

Specialized for Power Electronics & Control Systems

This thick copper PCB is particularly advantageous in applications involving converters, inverters, automotive power systems, and industrial control boards. It allows manufacturers to reduce circuit complexity by integrating fewer traces for the same performance, resulting in more compact and efficient assemblies. Flexible circuit board users in energy, automotive, and LED industries will benefit from its resilience and simplified heat sink requirements. Meidear’s commitment to pcb services ensures that each solution meets specific industry challenges.

Product Advantages

Reinforced Conductive Layer Enables High Current Loads

The 8oz copper build is not just about thickness—it’s an engineering choice to meet high current delivery without performance degradation. This multi-layered reinforcement allows for compact routing of power paths while reducing the need for excessive copper pours. Its enhanced ampacity rating makes it a preferred pick among pcb manufacturer portfolios and highly trusted in power pcb integration projects.

Heat Management Optimization Without External Sinks

With natural thermal dispersion capabilities embedded in the copper layers, this PCB minimizes hot spots and delays thermal failure. The reduction in reliance on external heat sinks not only saves space but improves long-term system reliability. For developers working on led pcb or compact flex pcb assemblies, this feature directly translates to a lower total system cost and reduced maintenance needs.

Compatibility With Hybrid And Modular Power Systems

Thanks to its heavy copper design and stable base material, this board integrates smoothly into modular assemblies. Whether you’re building smart converters or scalable power banks, this flexible circuit board ensures uniform voltage handling across modules. Its structural rigidity supports mechanical interfacing, making it ideal for system-level pcb services involving enclosure integration and dynamic load balancing.

Use Scenarios

Industrial Control Engineers Developing Power Modules

When designing high-power industrial controllers for automated machinery, control engineers rely on boards that can carry significant current loads without adding risk. Meidear’s 8oz copper PCB offers the electrical integrity and thermal performance needed to ensure long-term reliability, making it a valuable asset among pcb suppliers for power pcb configurations in automation panels.

Automotive Designers Crafting EV Inverter Systems

In electric vehicle powertrains, inverters and converters must handle sudden surges and rapid load shifts. Automotive hardware designers integrating DC-DC converters or regenerative braking circuits benefit from this flexible pcb for its current tolerance and temperature stability. It stands out among pcb manufacturer offerings due to its tailored heavy copper profile, ideal for modern EV infrastructure.

LED System Integrators Needing Stable High Current Paths

Large-scale LED arrays or high-lumen industrial lighting require PCBs that can safely carry large currents without overheating. This board offers a stable platform for lighting engineers and fixture designers dealing with thermal runaway prevention. Meidear’s product ensures that led pcb reliability aligns with long operating cycles and stringent brightness control, a key consideration for pcb services in lighting systems.

About Us

Meidear is a specialized pcb manufacturer headquartered in China, with a proven focus on delivering precision-engineered circuit boards for diverse industries. From flexible pcb to thick copper power solutions, the company supports prototyping to mass production with dedicated engineering support. Meidear partners with global clients in automotive, industrial automation, medical equipment, and consumer electronics sectors. By investing in advanced fabrication equipment and adhering to strict quality protocols, Meidear delivers customized pcb services that align with evolving industry standards. With a reputation for innovation and reliability, Meidear continues to grow as a trusted name among professional pcb suppliers.

Request your customized heavy copper flexible pcb solution from Meidear’s expert team today!

FAQ

What layer structure is used in the 8oz thick copper PCB?

It uses a multi-layer structure with FR4 substrate and 8oz copper per layer, ensuring strength and heat control.

Is technical consultation available before production?

Yes, Meidear provides engineering support to validate layout, copper weight, and thermal parameters before fabrication.

Can this PCB integrate with flexible circuits in hybrid assemblies?

Yes, it’s compatible with hybrid setups involving flex pcb and rigid-flex designs, ideal for modular integration.

What is the standard lead time for production?

Typical lead time ranges from 7–15 days, depending on order volume and customization specifics.

How does Meidear ensure product quality and reliability?

Each PCB undergoes AOI inspection, electrical testing, and impedance validation before shipment.

Get in touch with us at www.meidearpcb.com

or mail to mkt@me-pcb.com

Designed For High Current Power Systems

The 8oz Thick Copper PCB is purpose-built for high-current and power-intensive applications that demand robust electrical conductivity and superior heat control. Targeted at engineers, power electronics designers, and system integrators, this board is ideal for those seeking durability under extreme electrical loads. By offering exceptional thermal management and current-carrying capacity, Meidear empowers professionals in industries where performance under pressure is non-negotiable. Trusted by global pcb suppliers, this solution addresses the real-world needs of flexible pcb users.

Technical Configuration & Copper Thickness Superiority

At the heart of this board lies its defining feature: an 8oz (approximately 280μm) heavy copper layer. This significantly boosts current endurance and lowers the risk of circuit fatigue or failure. The PCB base is constructed with high-quality FR4 and offers advanced heat dissipation across all layers. With excellent solder mask finish and precise etching, the product also ensures mechanical stability even in fluctuating thermal environments. It is a standout among flex pcb and power pcb options offered by top-tier pcb suppliers.

Specialized for Power Electronics & Control Systems

This thick copper PCB is particularly advantageous in applications involving converters, inverters, automotive power systems, and industrial control boards. It allows manufacturers to reduce circuit complexity by integrating fewer traces for the same performance, resulting in more compact and efficient assemblies. Flexible circuit board users in energy, automotive, and LED industries will benefit from its resilience and simplified heat sink requirements. Meidear’s commitment to pcb services ensures that each solution meets specific industry challenges.

Product Advantages

Reinforced Conductive Layer Enables High Current Loads

The 8oz copper build is not just about thickness—it’s an engineering choice to meet high current delivery without performance degradation. This multi-layered reinforcement allows for compact routing of power paths while reducing the need for excessive copper pours. Its enhanced ampacity rating makes it a preferred pick among pcb manufacturer portfolios and highly trusted in power pcb integration projects.

Heat Management Optimization Without External Sinks

With natural thermal dispersion capabilities embedded in the copper layers, this PCB minimizes hot spots and delays thermal failure. The reduction in reliance on external heat sinks not only saves space but improves long-term system reliability. For developers working on led pcb or compact flex pcb assemblies, this feature directly translates to a lower total system cost and reduced maintenance needs.

Compatibility With Hybrid And Modular Power Systems

Thanks to its heavy copper design and stable base material, this board integrates smoothly into modular assemblies. Whether you’re building smart converters or scalable power banks, this flexible circuit board ensures uniform voltage handling across modules. Its structural rigidity supports mechanical interfacing, making it ideal for system-level pcb services involving enclosure integration and dynamic load balancing.

Use Scenarios

Industrial Control Engineers Developing Power Modules

When designing high-power industrial controllers for automated machinery, control engineers rely on boards that can carry significant current loads without adding risk. Meidear’s 8oz copper PCB offers the electrical integrity and thermal performance needed to ensure long-term reliability, making it a valuable asset among pcb suppliers for power pcb configurations in automation panels.

Automotive Designers Crafting EV Inverter Systems

In electric vehicle powertrains, inverters and converters must handle sudden surges and rapid load shifts. Automotive hardware designers integrating DC-DC converters or regenerative braking circuits benefit from this flexible pcb for its current tolerance and temperature stability. It stands out among pcb manufacturer offerings due to its tailored heavy copper profile, ideal for modern EV infrastructure.

LED System Integrators Needing Stable High Current Paths

Large-scale LED arrays or high-lumen industrial lighting require PCBs that can safely carry large currents without overheating. This board offers a stable platform for lighting engineers and fixture designers dealing with thermal runaway prevention. Meidear’s product ensures that led pcb reliability aligns with long operating cycles and stringent brightness control, a key consideration for pcb services in lighting systems.

About Us

Meidear is a specialized pcb manufacturer headquartered in China, with a proven focus on delivering precision-engineered circuit boards for diverse industries. From flexible pcb to thick copper power solutions, the company supports prototyping to mass production with dedicated engineering support. Meidear partners with global clients in automotive, industrial automation, medical equipment, and consumer electronics sectors. By investing in advanced fabrication equipment and adhering to strict quality protocols, Meidear delivers customized pcb services that align with evolving industry standards. With a reputation for innovation and reliability, Meidear continues to grow as a trusted name among professional pcb suppliers.

Request your customized heavy copper flexible pcb solution from Meidear’s expert team today!

FAQ

What layer structure is used in the 8oz thick copper PCB?

It uses a multi-layer structure with FR4 substrate and 8oz copper per layer, ensuring strength and heat control.

Is technical consultation available before production?

Yes, Meidear provides engineering support to validate layout, copper weight, and thermal parameters before fabrication.

Can this PCB integrate with flexible circuits in hybrid assemblies?

Yes, it’s compatible with hybrid setups involving flex pcb and rigid-flex designs, ideal for modular integration.

What is the standard lead time for production?

Typical lead time ranges from 7–15 days, depending on order volume and customization specifics.

How does Meidear ensure product quality and reliability?

Each PCB undergoes AOI inspection, electrical testing, and impedance validation before shipment.