CEM-3

CEM-3 supplier in shenzhen Meidear pcb

Item No.: CEM-3-006

CEM-3 copper clad laminate

CEM-3 pcb for led lighting solutions

Shenzhen original factory cem-1 94v-0/cem 1 /cem-3/cem 3 94v0 pcb circuit board

CEM-3 pcb for led lighting solutions

Shenzhen original factory cem-1 94v-0/cem 1 /cem-3/cem 3 94v0 pcb circuit board

Description

CEM-3

Composite base Copper Clad Laminate

Excellent cost performance

Excellent appearance

Excellent machining property

Application:

Apparatus and instrument / information household apliances / automotive electronics / remote control units / game machine and etc.

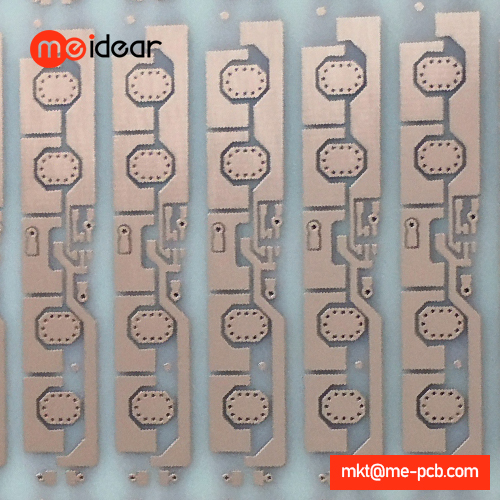

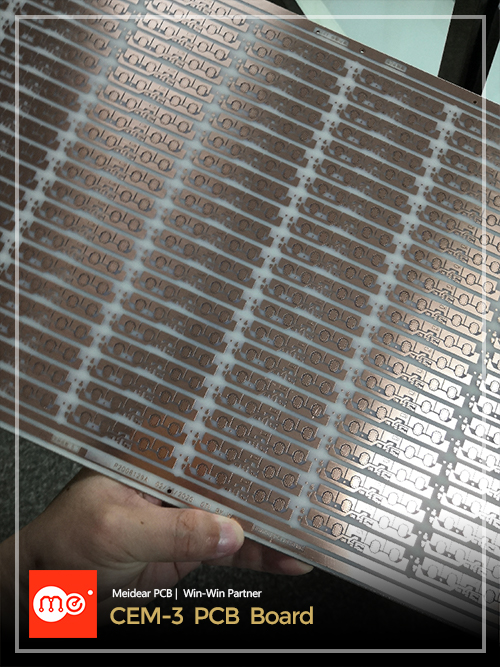

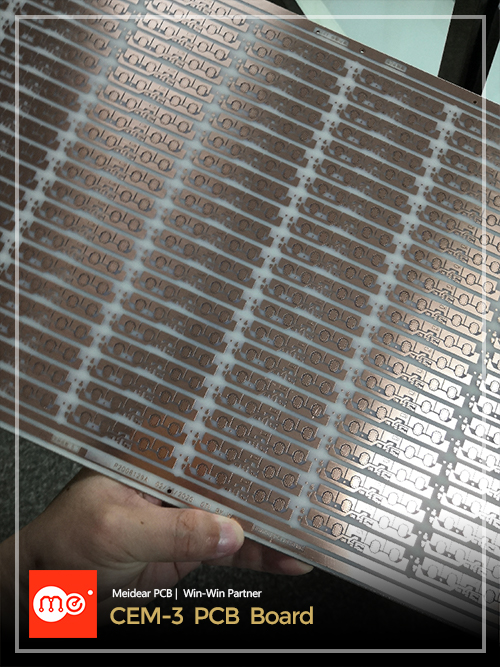

CEM-3 PCB Board Etching

Shenzhen original factory cem-1 94v-0/cem 1 /cem-3/cem 3 94v0 pcb circuit board

CEM-3 Copper clad laminate CCL full sheet for PCB

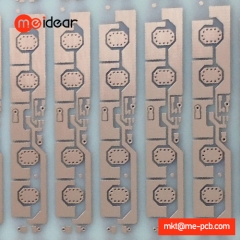

CEM-3 PCB Board Pattern transfer AOI

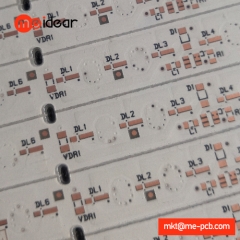

CEM-3 PCB Board Surface finishing: OSP

CEM-3 PCB Board Packing

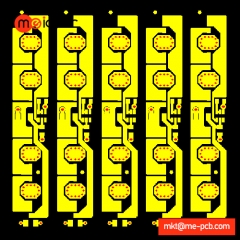

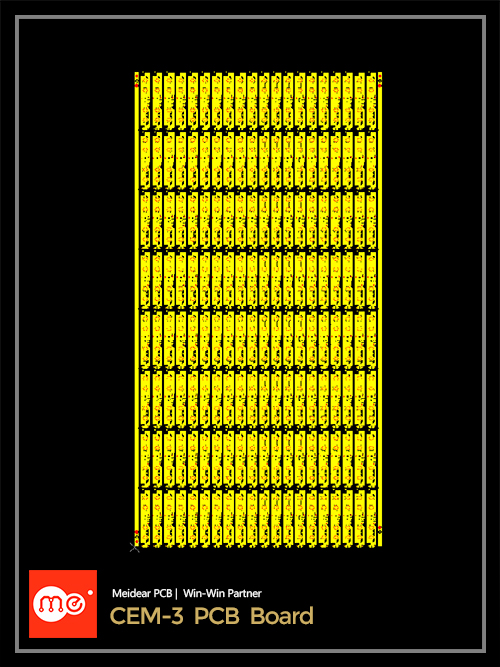

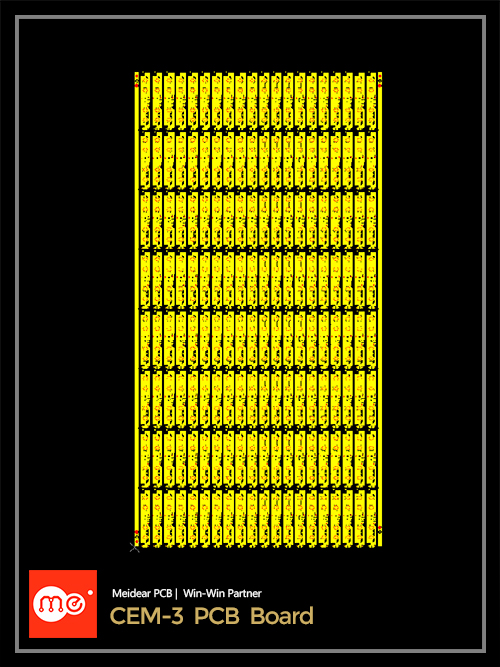

CEM-3 PCB Board Gerber Files GTL

Specialized customized 94v-0 fr-4 / cem-1 / cem-3 / PCB, Shenzhen professional pcb custom-made manufacturer

Excellent appearance

Excellent machining property

Application:

Apparatus and instrument / information household apliances / automotive electronics / remote control units / game machine and etc.

CEM-3 PCB Board Etching

Shenzhen original factory cem-1 94v-0/cem 1 /cem-3/cem 3 94v0 pcb circuit board

CEM-3 Copper clad laminate CCL full sheet for PCB

CEM-3 PCB Board Pattern transfer AOI

CEM-3 PCB Board Surface finishing: OSP

CEM-3 PCB Board Packing

CEM-3 PCB Board Gerber Files GTL

Specialized customized 94v-0 fr-4 / cem-1 / cem-3 / PCB, Shenzhen professional pcb custom-made manufacturer

1.CEM-3 Rigid LED PCB for LED Lighting Manufacturer.

2.Over 15 years experience in pcb manufacturing.

3.Design and produce almost any pcb as your requirement.

4.One-stop led pcb circuit board service, big scale of producing makes sure that your cost is lower.

5.100% testing guarantees stable quality, ISO 9001:2015 ,UL, RoHS & CQC.

As a PCB manufacturer.The good quality and good price for pcb is our choose for you.

Please give us your gerber files and specifications of pcb for a quote. We can deal with CAM350,protel99se and PADS.

Targeted For LED Lighting Assemblies And Cost-Effective Circuits

This CEM-3 based board is designed for LED lighting integrators and OEMs that require affordable and dimensionally stable substrates. It offers an alternative to traditional FR4 while maintaining sufficient dielectric strength for low-to-medium power applications. Known among pcb suppliers for its balanced performance-to-cost ratio, this solution is frequently used in interior lighting, signage, and backlight display panels. As a trusted pcb manufacturer, the provider ensures stable delivery and configuration options tailored to illumination systems.

Key Material Composition And Technical Structure

CEM-3 is a composite material consisting of woven glass fabric and non-woven glass core with epoxy resin, engineered to achieve Class 94V-0 flame resistance and electrical insulation. Unlike FR4, CEM-3 features a white surface ideal for led pcb reflectivity and aesthetic integration. It is manufactured in single or double-sided copper-clad formats with options for HASL or OSP surface finishes. These boards meet standard solderability, thermal resistance, and hole-wall reliability thresholds, making them suitable for flexible circuit board adaptation in stable environments.

Suitable For Consumer Lighting, Panels, And Modular Displays

This product is widely implemented in LED bulb bases, ceiling lighting strips, advertising boards, and indicator backplates. The material's smooth drilling and good adhesion make it adaptable for surface-mount technology and conventional through-hole components. Lighting system developers prefer this board for its price competitiveness and reliable light reflectance properties. Positioned between FR1 and FR4 in cost-performance hierarchy, it supports large-batch pcb services where mechanical demands are moderate and optical clarity is prioritized by pcb suppliers and end-product assemblers.

Product Advantages

White Surface Layer Enhances Optical Reflectivity

The CEM-3 board’s naturally white resin surface offers strong light reflectivity, making it a preferred substrate in led pcb design. It improves brightness efficiency and uniformity in lighting assemblies. This is especially critical in backlight modules, where uniform illumination is essential. Among pcb manufacturer offerings, this feature distinguishes CEM-3 as a material optimized not only for cost but also for visual performance.

Efficient Mechanical Processing For Large-Volume Runs

CEM-3 boards allow for smooth punching, drilling, and edge routing, supporting low-cost production without sacrificing precision. Its moderate hardness avoids the excessive tool wear seen in FR4 while still providing good layer stability. For pcb services that involve mass panelization and assembly line soldering, this ease of processing reduces operational costs and enhances throughput. Many flexible pcb manufacturer operations choose CEM-3 when balance between machinability and board strength is required.

Electrical Stability For Indoor Power Delivery Circuits

While lighter than FR4, the CEM-3 structure provides sufficient dielectric resistance and insulation reliability for indoor circuits under controlled loads. Its ability to support consistent signal transmission and LED driving voltages makes it suitable for modular power pcb setups. The reinforced epoxy core ensures long-term performance in humidity-controlled environments, ensuring compliance with typical circut board safety benchmarks.

Use Scenarios

OEM Lighting Assembly Teams Building Ceiling Modules

Lighting manufacturers often require high-volume, cost-optimized PCBs for domestic ceiling fixtures and LED bulbs. CEM-3 boards offer a stable mounting base for LED chips while contributing to visual consistency. With proper solder mask alignment and surface finish, these led pcb units integrate seamlessly into commercial ceiling light production—sourced through high-volume pcb suppliers with tight tolerance standards.

Visual Display Technicians Assembling Backlight Panels

Backlit signage, advertising boards, and LCD modules rely on consistent light diffusion, where CEM-3’s white finish becomes a functional advantage. Display technicians choose this material for its optical neutrality, solder pad consistency, and adaptability to low-current driver boards. These flexible circuit board formats are optimized for matrix-style layouts in static display environments, supported by reliable pcb services to meet dimensional and reflectance requirements.

Consumer Electronics Contractors Developing Indicator Boards

Contract manufacturers producing devices with status indicators—such as routers, smart appliances, or thermostats—benefit from CEM-3’s low warpage and stable thermal handling. The board's ability to host SMD LEDs on a cost-controlled surface reduces BOM pressure while maintaining compatibility with standard reflow soldering. When collaborating with a capable pcb manufacturer, contractors can scale production efficiently using CEM-3 as a structural base for flex pcb lighting modules.

About Us

This supplier specializes in PCB fabrication across a wide range of substrates including FR4, CEM-3, aluminum, and flexible polyimide. With a comprehensive facility equipped for prototyping and high-volume production, they serve clients in lighting, automotive, industrial control, and consumer device sectors. Their strength lies in offering scalable pcb services, engineering assistance, and tight-process quality control. As a professional pcb manufacturer, they deliver tailored solutions for both standard and customized circut board requirements, supporting global customers with short lead times and consistent quality assurance. They are also recognized among global pcb suppliers for their material diversity, surface finish options, and manufacturing transparency—making them a trusted partner for both rigid and flexible pcb development.

Send your led pcb design for CEM-3 fabrication and get professional support immediately!

FAQ

Is CEM-3 suitable for high-temperature environments?

CEM-3 is recommended for low to medium heat applications; for higher thermal loads, FR4 or metal-core options are advised.

What surface finishes are available for this board?

Available finishes include HASL and OSP, supporting both manual and automated soldering.

Can this board support double-sided assembly?

Yes, CEM-3 PCBs are available in single- and double-sided copper layouts, suitable for various LED designs.

How long is the production lead time?

Standard lead time ranges from 5 to 12 working days depending on order volume and complexity.

Is the material compliant with UL94V-0 flame-retardant standards?

Yes, the CEM-3 substrate meets UL94V-0 certification for flame resistance.

2.Over 15 years experience in pcb manufacturing.

3.Design and produce almost any pcb as your requirement.

4.One-stop led pcb circuit board service, big scale of producing makes sure that your cost is lower.

5.100% testing guarantees stable quality, ISO 9001:2015 ,UL, RoHS & CQC.

As a PCB manufacturer.The good quality and good price for pcb is our choose for you.

Please give us your gerber files and specifications of pcb for a quote. We can deal with CAM350,protel99se and PADS.

Targeted For LED Lighting Assemblies And Cost-Effective Circuits

This CEM-3 based board is designed for LED lighting integrators and OEMs that require affordable and dimensionally stable substrates. It offers an alternative to traditional FR4 while maintaining sufficient dielectric strength for low-to-medium power applications. Known among pcb suppliers for its balanced performance-to-cost ratio, this solution is frequently used in interior lighting, signage, and backlight display panels. As a trusted pcb manufacturer, the provider ensures stable delivery and configuration options tailored to illumination systems.

Key Material Composition And Technical Structure

CEM-3 is a composite material consisting of woven glass fabric and non-woven glass core with epoxy resin, engineered to achieve Class 94V-0 flame resistance and electrical insulation. Unlike FR4, CEM-3 features a white surface ideal for led pcb reflectivity and aesthetic integration. It is manufactured in single or double-sided copper-clad formats with options for HASL or OSP surface finishes. These boards meet standard solderability, thermal resistance, and hole-wall reliability thresholds, making them suitable for flexible circuit board adaptation in stable environments.

Suitable For Consumer Lighting, Panels, And Modular Displays

This product is widely implemented in LED bulb bases, ceiling lighting strips, advertising boards, and indicator backplates. The material's smooth drilling and good adhesion make it adaptable for surface-mount technology and conventional through-hole components. Lighting system developers prefer this board for its price competitiveness and reliable light reflectance properties. Positioned between FR1 and FR4 in cost-performance hierarchy, it supports large-batch pcb services where mechanical demands are moderate and optical clarity is prioritized by pcb suppliers and end-product assemblers.

Product Advantages

White Surface Layer Enhances Optical Reflectivity

The CEM-3 board’s naturally white resin surface offers strong light reflectivity, making it a preferred substrate in led pcb design. It improves brightness efficiency and uniformity in lighting assemblies. This is especially critical in backlight modules, where uniform illumination is essential. Among pcb manufacturer offerings, this feature distinguishes CEM-3 as a material optimized not only for cost but also for visual performance.

Efficient Mechanical Processing For Large-Volume Runs

CEM-3 boards allow for smooth punching, drilling, and edge routing, supporting low-cost production without sacrificing precision. Its moderate hardness avoids the excessive tool wear seen in FR4 while still providing good layer stability. For pcb services that involve mass panelization and assembly line soldering, this ease of processing reduces operational costs and enhances throughput. Many flexible pcb manufacturer operations choose CEM-3 when balance between machinability and board strength is required.

Electrical Stability For Indoor Power Delivery Circuits

While lighter than FR4, the CEM-3 structure provides sufficient dielectric resistance and insulation reliability for indoor circuits under controlled loads. Its ability to support consistent signal transmission and LED driving voltages makes it suitable for modular power pcb setups. The reinforced epoxy core ensures long-term performance in humidity-controlled environments, ensuring compliance with typical circut board safety benchmarks.

Use Scenarios

OEM Lighting Assembly Teams Building Ceiling Modules

Lighting manufacturers often require high-volume, cost-optimized PCBs for domestic ceiling fixtures and LED bulbs. CEM-3 boards offer a stable mounting base for LED chips while contributing to visual consistency. With proper solder mask alignment and surface finish, these led pcb units integrate seamlessly into commercial ceiling light production—sourced through high-volume pcb suppliers with tight tolerance standards.

Visual Display Technicians Assembling Backlight Panels

Backlit signage, advertising boards, and LCD modules rely on consistent light diffusion, where CEM-3’s white finish becomes a functional advantage. Display technicians choose this material for its optical neutrality, solder pad consistency, and adaptability to low-current driver boards. These flexible circuit board formats are optimized for matrix-style layouts in static display environments, supported by reliable pcb services to meet dimensional and reflectance requirements.

Consumer Electronics Contractors Developing Indicator Boards

Contract manufacturers producing devices with status indicators—such as routers, smart appliances, or thermostats—benefit from CEM-3’s low warpage and stable thermal handling. The board's ability to host SMD LEDs on a cost-controlled surface reduces BOM pressure while maintaining compatibility with standard reflow soldering. When collaborating with a capable pcb manufacturer, contractors can scale production efficiently using CEM-3 as a structural base for flex pcb lighting modules.

About Us

This supplier specializes in PCB fabrication across a wide range of substrates including FR4, CEM-3, aluminum, and flexible polyimide. With a comprehensive facility equipped for prototyping and high-volume production, they serve clients in lighting, automotive, industrial control, and consumer device sectors. Their strength lies in offering scalable pcb services, engineering assistance, and tight-process quality control. As a professional pcb manufacturer, they deliver tailored solutions for both standard and customized circut board requirements, supporting global customers with short lead times and consistent quality assurance. They are also recognized among global pcb suppliers for their material diversity, surface finish options, and manufacturing transparency—making them a trusted partner for both rigid and flexible pcb development.

Send your led pcb design for CEM-3 fabrication and get professional support immediately!

FAQ

Is CEM-3 suitable for high-temperature environments?

CEM-3 is recommended for low to medium heat applications; for higher thermal loads, FR4 or metal-core options are advised.

What surface finishes are available for this board?

Available finishes include HASL and OSP, supporting both manual and automated soldering.

Can this board support double-sided assembly?

Yes, CEM-3 PCBs are available in single- and double-sided copper layouts, suitable for various LED designs.

How long is the production lead time?

Standard lead time ranges from 5 to 12 working days depending on order volume and complexity.

Is the material compliant with UL94V-0 flame-retardant standards?

Yes, the CEM-3 substrate meets UL94V-0 certification for flame resistance.