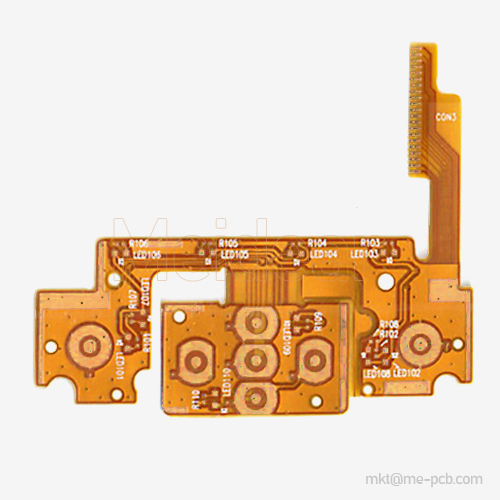

Single Sided Flexible PCB

FPC keypad used for High-end Medical Device supplier

Item No.: F000135

1L Coverlay yellow

hard gold (cobalt)

Electro-Deposited copper

Rolled Annealed copper

hard gold (cobalt)

Electro-Deposited copper

Rolled Annealed copper

Description

1L Coverlay Layer for Durable Encapsulation

This FPC keypad product employs a single-layer (1L) coverlay that provides protective encapsulation over conductive traces, suited for environments demanding precise key mapping and clean surface integrity. The coverlay enhances both insulation and mechanical protection, supporting designers and manufacturers seeking flexible construction in compact medical interface modules. Medical device engineers, input device designers, and OEM purchasers benefit from the keypad’s optimized layout and reliable cover encapsulation—showcasing manufacturing expertise as a flexible pcb manufacturer and trusted pcb supplier in sensitive applications.

Dual Copper Approach with Electro‑Deposited & Rolled‑Annealed Layers

The keypad integrates two copper types: electro-deposited copper for fine feature definition and rolled‑annealed copper for enhanced flexibility and current handling. Electro-deposited copper ensures precision in narrow trace widths required by tactile keypad layouts, while rolled‑annealed copper delivers ductile resilience, minimizing fatigue during flexing. These technical choices support both signal integrity and repeated use performance. As a specialist in pcb services and circut board fabrication, this design reflects a thoughtful balance of rigidity and flexibility demanded by high-end input systems.

Tailored for High‑End Medical Keypad Applications

Developed for demanding medical device applications, this FPC keypad aligns with stringent cleanliness, reliability, and ergonomic interface needs. The flexible circuit enables low-profile integration within hand-held or panel-mounted input devices—critical in environments like diagnostic tools or monitoring systems. Medical equipment engineers and procurement teams gain a finely engineered keypad that supports both assembly and sterilization procedures. As a flexible circuit board solution from experienced pcb suppliers, it addresses key functionality and regulatory-aligned construction in compact medical platforms.

Product Advantages

Protective Encapsulation via 1L Coverlay Enhances Durability

The single-layer coverlay not only safeguards copper traces from wear and cleaning agents commonly used in medical environments but also provides a smooth touch surface for keypad actuations. This enables repeated tactile use with minimal contamination risk. The design prevents delamination and supports sterilization processes without affecting circuit integrity. As a competitive flex pcb advantage, it increases functional lifespan while reducing maintenance costs—an appealing feature for both pcb manufacturer and end-user medical product suites.

Complementary Copper Layers Offer Flexibility and Conductivity

The dual-copper strategy leverages electro-deposited copper for detailed circuit patterns—ensuring clarity in keypad switch grid—and rolled‑annealed copper for mechanical resilience under bending stress. Together, they facilitate both electrical clarity and physical adaptability, allowing the keypad to conform to curved housings or wearable strap geometries. This synergy exemplifies an advanced pcb services capability, enabling assembly into challenging form factors without sacrificing circuit reliability or performance.

Purpose-Built for Medical Interface Reliability

Designed specifically for high-end medical device keypads, this FPC demonstrates consistent electrical contact behavior even after numerous cycles. Its materials and construction are chosen to minimize contact resistance and maintain responsiveness—imperative in critical-use cases. The keypad supports straightforward integration into medical enclosures, with predictable behavior under temperature or humidity variations. Such robust design underscores the role of a dedicated pcb supplier delivering medically compliant flexible pcb components that meet both performance and regulatory expectations.

Use Scenarios

Medical Device Engineers Designing Input Panels

An engineer developing a handheld glucose monitor requires a slim yet durable keypad interface. The FPC keypad—with 1L coverlay and flexible copper layers—enables embedding directly into the device housing, maintaining surface smoothness for cleaning while ensuring reliable electrical contact. As a reputable flexible pcb manufacturer, we provide this keypad solution so design teams can preserve ergonomic layout and hygiene compliance without sacrificing functionality.

OEM Procurement Specialists Sourcing Interface Modules

An OEM sourcing components for surgical control panels needs a keypad that withstands frequent sterilization cycles. The 1L coverlay chassis provides contamination resistance, while the combination of copper types ensures flexibility without fracture risk. Working with experienced pcb suppliers offering this flex pcb solution allows procurement teams to align component durability and supply reliability under medical-grade standards.

Regulatory Validation Teams Testing Durability

A quality assurance team validating new infusion pumps must test keypad response over thousands of actuations. The pressure keypad’s materials resist wear and maintain trace integrity even under repetitive stress. With both electro‑deposited and rolled‑annealed copper, it supports fatigue-resistant performance. This circut board based keypad, provided by trusted pcb services providers, helps validation specialists close testing protocols with confidence in long-term reliability.

About Us

We are a technology-driven PCB manufacturer with focused expertise in flexible circuit solutions tailored for precision applications. Operating from Shenzhen, our facility emphasizes advanced FPC capabilities—including coverlay layering, dual copper processing, and fine-line patterning. Our flexible offerings serve demanding sectors such as medical devices, where packaging, sterilization, and interface responsiveness are essential. Integrated design review, manufacturing traceability, and quality systems underpin our delivery of consistent, high-performance keypad PCBs. Collaborating across R&D, procurement, and validation functions, we support compact interface modules with technical reliability and regulatory alignment through disciplined pcb services.

Send your design files to receive a tailored medical-grade FPC keypad quotation today!

FAQ

What materials are used in this FPC keypad?

It uses 1L coverlay plus electro‑deposited and rolled‑annealed copper to balance flexibility and precision.

Is the keypad compatible with medical cleaning protocols?

Yes. The 1L coverlay protects traces during sterilization and frequent surface cleaning.

Can this FPC handle repeated flexing without failure?

Yes. The rolled‑annealed copper layer provides fatigue resistance for repeated bending.

What applications suit this FPC keypad?

It fits compact, high-use interfaces such as handheld monitors, control panels, or surgical devices.

How do I request a quote or order samples?

Submit your layout or inquiry, and our team will provide a tailored FPC keypad quote and delivery options.

This FPC keypad product employs a single-layer (1L) coverlay that provides protective encapsulation over conductive traces, suited for environments demanding precise key mapping and clean surface integrity. The coverlay enhances both insulation and mechanical protection, supporting designers and manufacturers seeking flexible construction in compact medical interface modules. Medical device engineers, input device designers, and OEM purchasers benefit from the keypad’s optimized layout and reliable cover encapsulation—showcasing manufacturing expertise as a flexible pcb manufacturer and trusted pcb supplier in sensitive applications.

Dual Copper Approach with Electro‑Deposited & Rolled‑Annealed Layers

The keypad integrates two copper types: electro-deposited copper for fine feature definition and rolled‑annealed copper for enhanced flexibility and current handling. Electro-deposited copper ensures precision in narrow trace widths required by tactile keypad layouts, while rolled‑annealed copper delivers ductile resilience, minimizing fatigue during flexing. These technical choices support both signal integrity and repeated use performance. As a specialist in pcb services and circut board fabrication, this design reflects a thoughtful balance of rigidity and flexibility demanded by high-end input systems.

Tailored for High‑End Medical Keypad Applications

Developed for demanding medical device applications, this FPC keypad aligns with stringent cleanliness, reliability, and ergonomic interface needs. The flexible circuit enables low-profile integration within hand-held or panel-mounted input devices—critical in environments like diagnostic tools or monitoring systems. Medical equipment engineers and procurement teams gain a finely engineered keypad that supports both assembly and sterilization procedures. As a flexible circuit board solution from experienced pcb suppliers, it addresses key functionality and regulatory-aligned construction in compact medical platforms.

Product Advantages

Protective Encapsulation via 1L Coverlay Enhances Durability

The single-layer coverlay not only safeguards copper traces from wear and cleaning agents commonly used in medical environments but also provides a smooth touch surface for keypad actuations. This enables repeated tactile use with minimal contamination risk. The design prevents delamination and supports sterilization processes without affecting circuit integrity. As a competitive flex pcb advantage, it increases functional lifespan while reducing maintenance costs—an appealing feature for both pcb manufacturer and end-user medical product suites.

Complementary Copper Layers Offer Flexibility and Conductivity

The dual-copper strategy leverages electro-deposited copper for detailed circuit patterns—ensuring clarity in keypad switch grid—and rolled‑annealed copper for mechanical resilience under bending stress. Together, they facilitate both electrical clarity and physical adaptability, allowing the keypad to conform to curved housings or wearable strap geometries. This synergy exemplifies an advanced pcb services capability, enabling assembly into challenging form factors without sacrificing circuit reliability or performance.

Purpose-Built for Medical Interface Reliability

Designed specifically for high-end medical device keypads, this FPC demonstrates consistent electrical contact behavior even after numerous cycles. Its materials and construction are chosen to minimize contact resistance and maintain responsiveness—imperative in critical-use cases. The keypad supports straightforward integration into medical enclosures, with predictable behavior under temperature or humidity variations. Such robust design underscores the role of a dedicated pcb supplier delivering medically compliant flexible pcb components that meet both performance and regulatory expectations.

Use Scenarios

Medical Device Engineers Designing Input Panels

An engineer developing a handheld glucose monitor requires a slim yet durable keypad interface. The FPC keypad—with 1L coverlay and flexible copper layers—enables embedding directly into the device housing, maintaining surface smoothness for cleaning while ensuring reliable electrical contact. As a reputable flexible pcb manufacturer, we provide this keypad solution so design teams can preserve ergonomic layout and hygiene compliance without sacrificing functionality.

OEM Procurement Specialists Sourcing Interface Modules

An OEM sourcing components for surgical control panels needs a keypad that withstands frequent sterilization cycles. The 1L coverlay chassis provides contamination resistance, while the combination of copper types ensures flexibility without fracture risk. Working with experienced pcb suppliers offering this flex pcb solution allows procurement teams to align component durability and supply reliability under medical-grade standards.

Regulatory Validation Teams Testing Durability

A quality assurance team validating new infusion pumps must test keypad response over thousands of actuations. The pressure keypad’s materials resist wear and maintain trace integrity even under repetitive stress. With both electro‑deposited and rolled‑annealed copper, it supports fatigue-resistant performance. This circut board based keypad, provided by trusted pcb services providers, helps validation specialists close testing protocols with confidence in long-term reliability.

About Us

We are a technology-driven PCB manufacturer with focused expertise in flexible circuit solutions tailored for precision applications. Operating from Shenzhen, our facility emphasizes advanced FPC capabilities—including coverlay layering, dual copper processing, and fine-line patterning. Our flexible offerings serve demanding sectors such as medical devices, where packaging, sterilization, and interface responsiveness are essential. Integrated design review, manufacturing traceability, and quality systems underpin our delivery of consistent, high-performance keypad PCBs. Collaborating across R&D, procurement, and validation functions, we support compact interface modules with technical reliability and regulatory alignment through disciplined pcb services.

Send your design files to receive a tailored medical-grade FPC keypad quotation today!

FAQ

What materials are used in this FPC keypad?

It uses 1L coverlay plus electro‑deposited and rolled‑annealed copper to balance flexibility and precision.

Is the keypad compatible with medical cleaning protocols?

Yes. The 1L coverlay protects traces during sterilization and frequent surface cleaning.

Can this FPC handle repeated flexing without failure?

Yes. The rolled‑annealed copper layer provides fatigue resistance for repeated bending.

What applications suit this FPC keypad?

It fits compact, high-use interfaces such as handheld monitors, control panels, or surgical devices.

How do I request a quote or order samples?

Submit your layout or inquiry, and our team will provide a tailored FPC keypad quote and delivery options.